Upcycling chicken feathers among efforts to create Singapore’s first 'zero waste' poultry processing facility

A step-by-step depiction of how chicken feathers are washed and ground into keratin powder, and the packaging materials which they would be used to manufacture. (Photo: NTU Singapore)

SINGAPORE: The upcycling of chicken feathers and by-products are among the new processes developed by Nanyang Technological University (NTU) and poultry producer Leong Hup, as part of a push to create Singapore’s first “zero waste” poultry processing facility.

These processes to repurpose waste materials from poultry farming were developed under a research collaboration agreement signed in March, NTU and Leong Hup said in a news release on Tuesday (Jul 5).

One “key innovation” is the use of keratin from chicken feathers as a material for egg trays, serving as a biodegradable replacement for synthetic polymers.

It is also a greener alternative as the production, use and disposal of synthetic polymers results in greenhouse gas emissions as such polymers are made from petroleum oil.

“Yearly, billions of kilograms of unwanted chicken feathers are thrown out from poultry process plants,” NTU and Leong Hup said, adding that this by-product is typically either buried in landfills or incinerated.

Director of NTU’s Food Science and Technology programme, Professor William Chen said the project has demonstrated that feathers can no longer be viewed as a waste product.

"The utilisation of chicken feather fibres in composite materials is a new source of materials that can be economic, eco-friendly, and recyclable," added Prof Chen, who is also co-lead of the research collaboration.

The process starts with washing the chicken feathers in distilled water and detergent to remove contaminants such as bloodstains and oil. They are then dried at room temperature for four days and cut with a crushing machine.

The feather fibres and unsaturated polyester resin are mixed and placed inside glass moulds and kept in a fume hood for a day.

The end result is a material that is more durable when compared to synthetic polymer alternatives.

Laboratory tests found that the material made from chicken feather keratin could withstand nearly two times the force exerted on it, as compared to conventional plastic trays used to contain chicken meat, said NTU and Leong Hup.

CULTURE MEDIUM

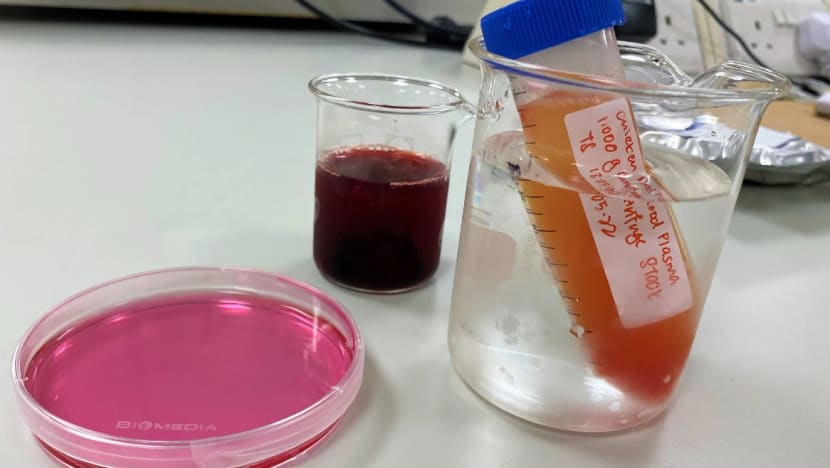

The research collaboration also developed a method to convert biological waste from poultry farming - such as blood and bones - into an alternative and cost-efficient culture medium that could be used to cultivate cell-based meat.

“Poultry blood and the by-products of processing animal and food products are dense in organic matter, and have high concentrations of growth factors and other nutrients,” said NTU and Leong Hup.

These include amino acids, vitamins, glucose, inorganic salts and growth factors.

“The NTU scientists have also managed to effectively extract those nutrients and develop a solution that has the potential to grow animal cells for lab-grown meat,” according to the news release.

“In recent tests, they also showed that the serum derived from poultry blood and biological matter has the potential to replace foetal bovine serum (a by-product of harvesting cattle) as a medium to cultivate cell-based meat, as it has similar concentrations of growth factors and other nutrients.”

Prof Chen said the processing of poultry blood to cultivate cell-based chicken meat could be a “step towards cutting down the carbon footprint of the food industry”.

Leong Hup Singapore CEO, Lau Joo Hwa added that the company is currently testing the innovations in its Singapore plant. The products developed with NTU are also expected to be implemented in overseas plants – such as in Malaysia and other parts of Southeast Asia – by next year.