The challenges entrepreneurs face in Singapore, and what it takes to succeed

Is Singapore a good place for inventors? What rejections should they be prepared for in running a start-up? Their struggles and successes speak of the limitations and support they found here, and the series Made in Singapore celebrates their talents.

Mr Kevin Chiam has designed four products catering for those with special needs or the elderly. But none have been fully commercialised owing to the limitations of time and finances.

SINGAPORE: Even before his invention is available for purchase, there has been a deluge of interest from around the world.

CNA Insider’s story last month about 26-year-old Kevin Chiam’s special cooking tools for the blind, designed to protect the visually impaired from injuries in the kitchen, has reached more than five million people.

READ AND WATCH: Young designer invents kitchenware for the blind, but struggles to bring it to market

And the responses include not only requests to buy his kitchenware for family, friends and colleagues but also support in terms of crowdfunding, marketing, mentorship, professional advice as well as logistics and distribution, he said.

But as an indication of the challenges that inventor-entrepreneurs like him face in Singapore, the commercial development of his set of kitchen utensils, called Folks, could still take “anywhere from months to perhaps a year or over”, he reckoned.

“Quality and functional checks are necessary to ensure that the products perform at the desired level. Marketing and distribution are also potential challenges that affect the product reach,” explained the designer.

The complications involved in manufacturing and bringing a project to the market – even one that could help a community worldwide – have been an issue for him, despite his best efforts to find suitable manufacturers to produce his business concept.

And it is a struggle others have faced here in creating a range of innovations, from square milk bottles to a drinks machine and high-tech thermal sensors to gadgets for niche pastimes, as the series Made in Singapore discovers.

Many of them have now made a success of their creations, even if users may not be aware of their home-grown origins. But it took hardship, sacrifice, risks, time and some luck to overcome the problems, rejections and failures.

LACK OF FUNDING

One of the biggest challenges is a lack of funding, according to Mr Chiam and Ms Esther Wang, the founder and chief executive officer of Joytingle, a health education company that explains healthcare concepts to children through play.

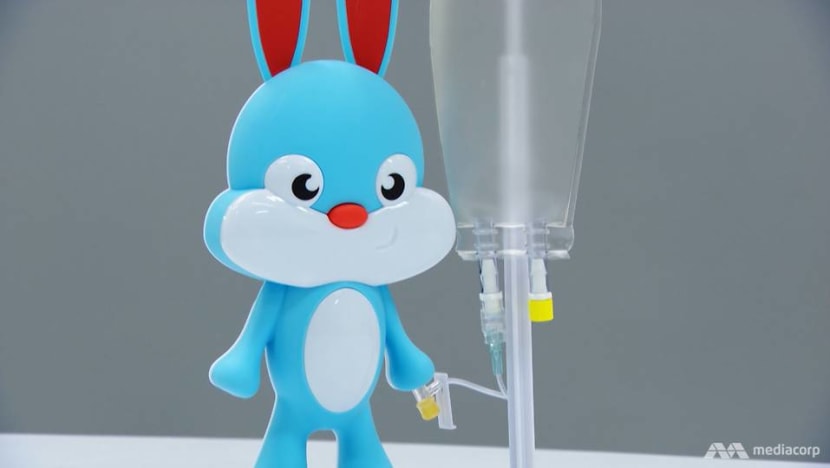

Joytingle’s flagship product is Rabbit Ray, an educational tool for teaching children about vaccination, blood-taking and how an intravenous drip is set up, which can reduce their anxieties about needles and hospitals.

The company, which started in 2012, has customers in 10 countries now. But it took four years of product development – “largely self-funded” – before Ms Wang’s patient engagement bunny became a reality.

“At that time, not a lot of people saw the potential that I saw. Moreover, in Singapore, most investors would favour ICT, electronics and telecommunication-based products,” said the 30-year-old, who went without a regular salary for that period.

She had to forgo holiday trips with friends and other material comforts, but was at a stage in her life where she could “afford to take this risk”.

As her peers moved ahead in their lives, however, she asked herself whether it was worth it.

“When I was left with my last S$8,000 in my bank, in front of me there were two choices: The first choice was to cut my losses … or the second choice, which I preferred, was to press on,” she said.

“My mum told me, ‘There are many people who want Joytingle to succeed. And they want to use Rabbit Ray. Don’t give up.’ And that gave me the motivation to continue.”

Eventually, she found investors, and it also helped to have mentors like Ms Renee Xavier, the founder of Alpha & Omega Law Corporation. “Esther’s quite an amazing person. She’s able to just get up and go again,” said the lawyer.

“We helped her with her patent. Patenting is an expensive journey. We taught her how to make it less expensive … and she worked really hard. So it was a real pleasure working with her because we could see that she was doing her best.”

In Mr Chiam’s case, he has joined competitions – like the Singapore Creative Awards launched this year – to gain recognition. And about 10 of his projects have won awards.

“Winning a competition definitely gives you the opportunity in terms of exposure if, let’s say, there are potential investors who are interested,” said the designer, who developed his cooking tools in his final year at the National University of Singapore.

“But it's not often the case.”

One reason that finances remain a limitation is the Singapore environment for start-ups.

Dr Yen Ching Chiuan, co-director of the Keio-NUS CUTE (Creating Unique Technology for Everyone) Centre, said: “(Design students) always face some problems because … the market is small. It’s not like in China. The investor is also much more conservative.”

MANUFACTURING WOES

Finding a suitable manufacturer here can also be as hard as obtaining investments – including, as Ms Wang put it, finding one that would “regard your product with the respect it deserves”.

“Most manufacturing firms are very used to large orders – big manufacturing runs, half a million units,” she said. That would make it challenging for entrepreneurs like her.

So it was a “great breakthrough” when she found a company that “understood (her) product’s intention” and was willing to work with her.

While she recognised that Singapore has a good manufacturing base – “that’s how we started in the 1960s and 70s” – she felt that the move towards a knowledge-based economy has affected the industry.

“To be a truly innovative country … we also need an ecosystem of people who can build (products). We need these local manufacturers,” she said.

She noted that high manpower and land costs are a reality that factory operators must confront, so she understood why there has been relocation overseas.

“But I’d say that Singapore manufacturers offer you the advantage of better quality control, better intellectual property protection and faster response time,” she said, explaining why she chose a domestic production line.

“If there’s any issue when we’re building a product, I could be there in 30 minutes instead of … having to take a plane.”

Mr Chiam agreed that there was an “industrial gap locally”, which he identified as “the most difficult part” in trying to commercialise his cooking set.

Countries like China and Vietnam have the space and are “more vibrant’ manufacturing centres, he said. “So there’s this limitation in terms of distance … (or) whether you're able to get certain materials (if manufactured in Singapore).”

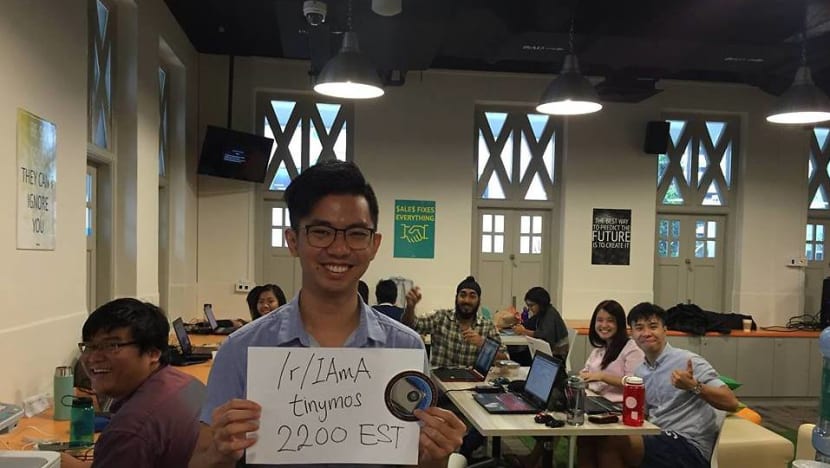

Mr Grey Tan, the co-founder and CEO of TinyMos, was one who faced problems during the manufacture of his invention, Tiny1, which is said to be the world’s smallest astronomy camera.

His design house partner chose a cheap set of electronics that did not support all the software requirements, which meant having to redesign the camera’s hardware electronics from scratch. “That really threw us off our timeline,” said the 28-year-old.

After the redesign the company found that there was interference with the wireless components as well.

“Those problems had to be fixed by specialised technicians who weren’t available in Singapore. We had to fly the whole chip to Taiwan (for) the antenna manufacturer to get those things sorted out,” he added.

“Once the problem was solved, (we then) had to buy new components that took weeks to arrive … So there were a lot of cascading technical challenges that we had to overcome to make the camera come to life.”

'FROM EUPHORIA TO SHEER TERROR'

While Mr Tan and his team may have expected the making of an astro-camera to be complex, one thing that caught them off guard was the naysayers reacting to the company’s crowdfunding effort on the Kickstarter platform.

“We realised that on Reddit, there was a thread called ‘Shitty Kickstarter’ and … there were a lot of detractors saying that this is a fraud and we’re making fraudulent claims. And that got the team quite down,” he recounted.

His team tried to ignore the problem, but because it was a popular thread, it got to a point where they had to put out answers to questions people had about the campaign.

According to Mr Faruq Marican, the CEO and co-founder of Popsical, running a start-up is like “going from euphoria to sheer terror – you’re never really in between – and that’s the hardest part”.

“You can’t take time to enjoy the success or the traction,” said the 31-year-old. “The next day, you could face a terrible situation.”

His company created a streaming karaoke set that weighs 150 grammes, is shaped like a doughnut and fits in the palm of one’s hand. Through an app, it gives users access to an online library of more than 100,000 songs.

READ: Singapore's Popsical, X-mini partner to create compact karaoke speakers

A week before the device was to be shipped, however, a bug caused the music to come out of only one side of the speakers it would be plugged into, he recalled. Trying to fix it resulted in another bug.

“It was something that we totally didn’t foresee happening … (and) something that we didn’t even know we could solve. And if we were to ship that product, we would’ve been dead in the water,” he said.

“No one would want to use it ever again.”

But the company had an engineer who “recognised the gravity of the situation”, got to work and figured out a solution. “So that support structure is super important,” added Mr Marican.

“You need talented people to help you solve these issues. And you need to be able to solve them with a steady hand … You can't really let that terror get to you – you just have to keep powering through.”

RESOLVE IN THE FACE OF REJECTION

Patience and resolve is needed, as Mr Tushar Mohan, the co-founder and CEO of Souschef, has also demonstrated.

He took about four years to create a customisable beverage dispenser – a digital bartender – only to find that the industry might not be as keen to automate as he is.

After a bubble tea deal in Malaysia fell through, his company reached out to bubble tea shops in Singapore, but to no avail. “We’ve had clients who’d reject us just because we were new,” said the 25-year-old.

Their reaction did not surprise Mr Alex Crompton, the managing director of Entrepreneur First Singapore, which helps start-ups. “You have to be prepared for 90 per cent of the people who’re supposed to say yes (to) say no,” he said.

“Tushar has been through that cycle, but he’s an incredibly resilient person. The lengths that he is willing to go to make it work is beyond what I’ve seen in many, many people.”

In April, Souschef reached out to Gong Cha and got a positive response this time.

Mr Andy Oh, the chief operating officer of the bubble tea chain in Singapore, said: “This digital bar is only the very first step in our very ambitious plan to automate … We want to maintain the consistent quality, so this kind of auto-dispenser will come in handy.”

Another inventor who has dealt with her fair share of sceptics and rejections is Ms Pranoti Nagarkar, the co-founder and co-CEO of Zimplistic, the company behind the automated flatbread-making machine, Rotimatic.

READ: Zimplistic, company behind Rotimatic, raises S$39.3m in series C funding

There were people who “only saw challenges” and said the machine would not be possible or not cheap to make or too huge, let alone make a good roti.

There were potential investors who said “give me a 70 per cent stake in the company, and I’ll give you just some amount of money”, recalled the 36-year-old.

And then there were those who did not take her seriously as a female engineer.

“They thought that I was the marketing person or business person because that’s a stereotype you see and not many women in technology, especially hardware technology,” she said.

One of the ways she tried to break that stereotype was by going around in her heavy cruiser motorcycle and helmet, which they would not have thought she could do, she reasoned.

Another initial impression people had was that she was a student, as she was working out of an NUS incubator space for a time.

She had to explain to them that it was she who started the company and that there was no professor helping or “going to join in the meeting”. In time, the stereotypes went away.

“There was always that resolve that would become stronger whenever there was a rejection,” she said.

TIRING BUT WORTH THE JOURNEY

It is already a feat to be an entrepreneur, let alone one who is also a mother with an “equally challenging” job of running a household, said Hegen founder and managing director Yvon Bock, who has four children.

In her case, it was her breastfeeding experience that inspired her to introduce a first-of-its-kind soft square feeding bottle, which is easier to stack and for babies to hold.

But it is “never easy” to balance business and family life. “I came to a point where I decided to say Hegen is my fifth baby,” said the 39-year-old.

“So when I put my mind to say that all five of them are equally important, then I don’t see it any more as a sacrifice but … as me doing my best for each one of them, at the point in time needed of me.”

The journey of innovation can be “very tiring”, admitted Ms Wang. Her advice for budding entrepreneurs?

“They need to ask themselves: Can they take this level of hardship, or even stomach the level of uncertainty that comes from bringing their product to reality?” she said.

For Mr Leonard Lim, there are no regrets after his company Omnisense Systems’ thermal sensors revolutionised the way fever screening is done, even though it was 12 years of “constant struggle” and a path littered with debt, despair and divorce.

READ: The Singaporean serial entrepreneur who kept failing, until he got a lucky break

“What I’m doing today is what I think I should be doing,” said the 48-year-old.

Parents, especially like my mum, would feel that it’s probably not worth it. In all honesty, I think she’d probably prefer I get a job.

“But, I guess, in all great journeys, you need to have a dream, be able to visualise what you want to achieve and be willing to sacrifice to be able to achieve those things," he added.

That journey has only just begun for Mr Chiam. But there is new hope “at this moment”: A local design studio with the “relevant industry experience” is interested in licensing his cooking tools.

“Talks between the design studio and the NUS Industry Liaison Office have been initiated,” he disclosed.

“The IP of the collection belongs to NUS – I am, however, credited as the inventor – and thus formal negotiations have to be made before any development can proceed.”

For his part, he knows what he wants, and recognition or profits “are not the main focal points”.

“I’m more than pleased if there are individuals who want to take the kitchenware to the market, even if I’m not credited, as long as the blind community can benefit from the endeavour,” he said.

The series Made in Singapore tells the stories of eight inventors and their inventions. Watch it here.