A glimpse into a supermarket's weighing and labelling process

Following a couple of supermarket "mislabelling" incidents where customers found their fresh food products were not labelled with the actual weight, CNA goes behind the counter at a Cold Storage supermarket to understand the significance of getting the weight right.

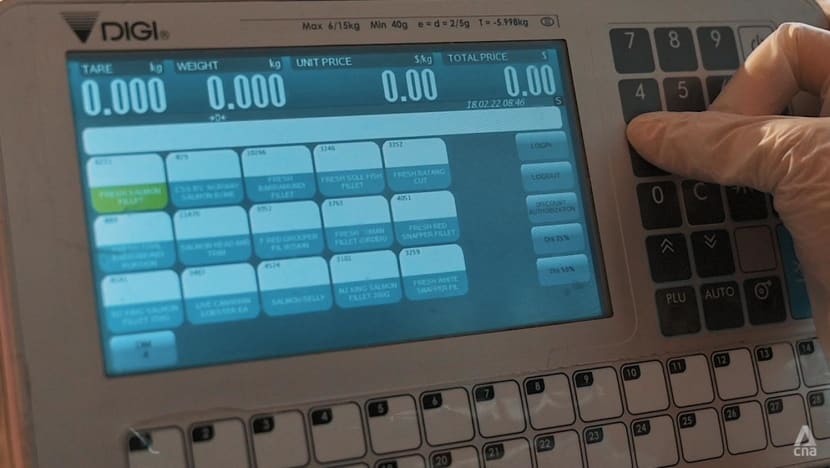

A weighing scale behind a counter at CS Fresh Gold in Paragon Shopping Centre. (Photo: CNA/Hanidah Amin)

SINGAPORE: Before the morning crowd streams in, supermarket employees all over the island busy themselves with various duties to get ready for the day.

One such duty involves ensuring the weighing scale at the fresh food station is “straight and even” and reset to zero, so customers receive the accurate weight of their produce before paying for it.

This task is so critical that there are even a few text and visual reminders plastered beside the weighing scale – at least for employees at CS Fresh Gold in Paragon Shopping Centre, operations director of Cold Storage, Mr Denesh Kumar, showed CNA.

Earlier in February, a packet of salmon sold at a FairPrice Xtra outlet was mislabelled. The customer’s TikTok video showed that its weight on a scale (0.176kg) was different from what was stated on its label (0.296kg). FairPrice said that this mislabelling incident was likely caused by human error.

Another TikTok video in the same month showed a packet of chicken mislabelled as 0.224kg, when it only weighed 0.165kg.

The videos prompted questions online about whether consumers should check the weight of their groceries.

In light of the incidents, CNA contacted supermarkets to learn about their weighing and labelling process – and got to peek behind the counter with Cold Storage one morning.

Related:

RESET SCALE TO ZERO, PERFORM “BUBBLE CHECK”

When team members start their shift every morning, the first step is resetting the scale to zero, said Mr Kumar.

“If they don’t do that, (the scale will reflect) the tare weight (of the previous item that was weighed). So the weight given to the customer might be wrong on the rare occasion that this happens. But they’re all trained that it’s set to zero.”

(The “tare weight” refers to the weight of the empty packaging before any food has been packed.)

“We’ve also installed a few reminders for the team members on their daily checks (to inform them) what they need to do and also a picture guide for them to look at,” added Mr Kumar.

Another critical step is performing a “bubble check” to ensure the weighing scale is “straight and even”, because “it’s very important for the weighing scale to be on a flat, even surface, so the weight is 100 per cent accurate”.

But when might the scale be "tilted"?

“We do have strict measurements with our food safety team. All our counters, the gradient, and the measurements are done before we even place the weighing scale. So on rare occasions when a team member might knock into it, or someone just slightly pushes it, it might go uneven,” said Mr Kumar.

“So that’s where the bubble check comes into play, where every morning they need to check that the bubble is within the red circle.”

Usually, once the bubble check is done, the bubble won’t move unless the scale moves, added Mr Kumar.

There is also a “built-in culture” where employees are trained to keep an eye on the bubble as they are weighing their product on the scale, he shared.

In addition to these daily checks, Cold Storage adheres to Enterprise Singapore’s guidelines on the Weights and Measures Act by working with “authorised verifiers” to “calibrate our scale once a year across all stores and in all departments”.

GETTING THE TARE WEIGHT

Once the daily checks are done, when customers are buying the seafood, employees would first measure the tray’s tare weight. This means placing the empty tray, the absorbent pad and the shrink wrap onto the scale.

Then employees press the "T" button to lock in the tare weight for that specific packaging.

For instance, if the tare weight is 0.014kg, the scale will be set to -0.014kg before any fresh meat is placed into the empty tray. This is so the final weight calculated for the customer’s product will be accurate.

To reassure customers that the employee doesn’t key in an erroneous figure, the customer can “see what we are doing”, said Mr Kumar, pointing to a double-sided reading scale that shows the customer the exact measurements on the screen facing the employee.

“Whatever I’m weighing here, the customer is also looking at it from there. So the customer can also see the weight.”

Despite the stringent checks that go to ensuring customers get their products labelled with the correct weight and price, human error can occur for a couple of reasons, suggested Mr Kumar.

First, the employee might not have measured the tare weight; second, the scale might not be calibrated.

SO WHAT’S THE BIG DEAL WITH LABELLING CORRECTLY?

Put simply, it's “very important” to get the weight right because of “integrity”, explained Mr Kumar.

“So customers can get what they are buying according to the weight they are purchasing.”

On top of this, the Weights and Measures Act that governs all retailers stipulates that products have to be sold accurately in terms of weight, because customers are paying for them, he added.

“I would say it’s very rare (for mislabelling incidents to happen) because our team members are trained really well. I think the TikToker reinforced that for us,” said Mr Kumar.

“Our team members go through a routine process, check and control training. We also have online training for them. … So it’s quite rare (for such incidents to happen). We’d rather give more (product) than less.”

But if miscalculation or mislabelling happens, Cold Storage encourages customers to quickly contact their store managers or their customer service department. The supermarket can then follow up with the customer on service recovery and provide a refund or exchange, noted Mr Kumar.

“Internally, what we will do is engage our food safety team and do a root-cause analysis. This means we'll find out from the customer’s feedback about what actually happened. So we will … be going into the deep-dive of the error and try to find out what caused the mislabelling or the weighing difference,” he added.

“And usually, it's due to the mishandling from the team members, (so) we'll quickly address the team members and send them for another refresher training.”