GEARING UP TO FIGHT COVID-19

We went through SARS 17 years ago, so we are much better prepared to deal with [COVID-19] this time. Practically, we have stockpiled adequate supplies of masks and personal protective equipment (PPE).

PM LEE HSIEN LOONG

FEB 8, 2020, REMARKS ON THE COVID-19 SITUATION

Besides ensuring adequate supplies of personal protective equipment (PPE) for frontline workers during the COVID-19 pandemic, Singapore also had to ensure that there were enough masks for the entire population.

While Singapore had a stockpile of PPE since the first SARS outbreak in 2003, supplies could be disrupted in the event of a sudden surge in demand, especially at a time of export bans in manufacturing hubs like China and the United States.

STRATEGIES TO ADDRESS THE CHALLENGE

After the SARS outbreak, the Strategic Resource Management Division was set up to ensure that critical medical supplies and material resources were ready and available in the event of future national emergencies.

When COVID-19 hit, various ministries and agencies stepped up to increase our medical supplies. They sourced for PPE in many countries and worked concurrently with local companies to design and produce masks.

A RESULT

OF OUR

COLLECTIVE

EFFORT

“We supported and trusted one another throughout this journey and have emerged stronger and more resilient as a nation. This is a hard-earned achievement.”

PM LEE HSIEN LOONG,

FEB 10, 2023, FACEBOOK POST

LOCAL COMPANIES LENDING SUPPORT

In April 2020, gaming company Razer announced that its fully automated mask manufacturing line was in operation and could produce about five million masks per month. In May 2020, Razer also set up 20 vending machines islandwide to provide five million free masks to Singapore residents.

A mask vending machine set up by Razer.

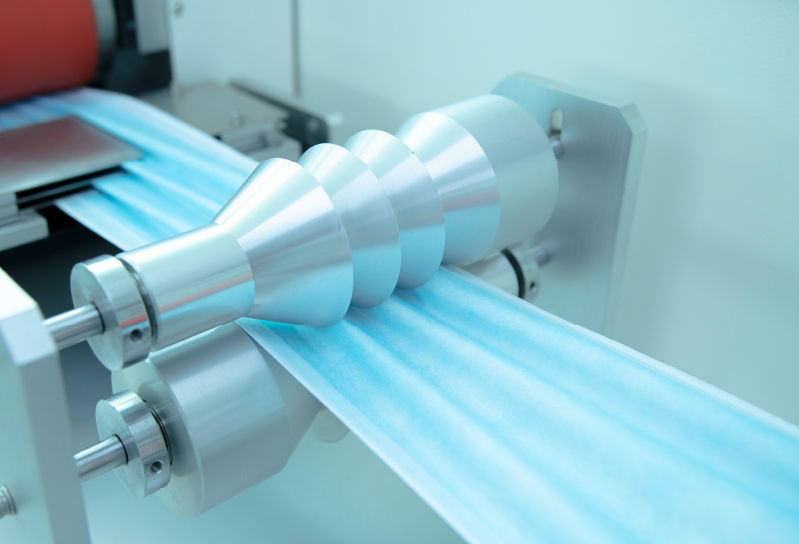

Some companies pivoted to manufacturing masks. AVS Technologies (which sells printing equipment) and apparel manufacturer Ramatex collaborated with A*STAR’s Singapore Institute of Manufacturing Technology (SIMTech) and Advanced Remanufacturing and Technology Centre (ARTC) to produce masks locally.

ST Engineering also began domestic production of surgical masks and by January 2021, the company was able to produce melt-blown polypropylene filters. This meant the production of higher-grade masks end-to-end locally.

MASKING UP AS BEST PRACTICE

On Feb 10, 2022, the MTF announced that Singapore would move to DORSCON Green and masks would only be required in healthcare settings with patient interactions. Masks would be optional in all other areas.

Singaporeans are still encouraged to put on their masks when they feel unwell as part of good public health and hygiene practices. The authorities will continue to ensure a robust supply chain and adequate stockpile of medical supplies, in preparation for future pandemics.

Photos: National University Health System and Razer