From lotus pond to high fashion: Myanmar weaves legacy of exquisite fabric

In Myanmar’s far-flung community, skilled artisans sit at their looms and weave one of the most expensive and finest fabrics in the world. It is made of lotus.

In a remote lake community of eastern Myanmar, local women weave one of the most precious and finest fabrics in the world, using lotus. (Photo: Pichayada Promchertchoo)

INLE, Myanmar: If there should be any textile fitting for faith and devotion, a piece of fine fabric meticulously woven by hand from the delicate fibres of tens of thousands of lotus stems is no doubt one of the top contenders.

Its modest look can easily deceive one into believing its creation is simple. It is all an illusion.

“A square metre of this fabric requires at least 20,000 lotus stems and takes a skilled artisan 40 days to produce,” said Myint Thein Htun, owner of the established lotus weaving centre Khit Sunn Yin.

His workshop, a spacious traditional wooden structure on stilts, is among the top tourist destinations on Inle Lake in Myanmar’s eastern Shan State.

Besides displaying an array of products made of hand-spun lotus threads, the space also functions as a learning centre for local women who have, on top of great patience and unshakable determination, an effervescent desire to weave this rare and exotic fabric.

The clickety-clack of numerous looms reverberating around the crowded workshop hints at the locals’ keen interest in the challenge of this handicraft. After all, there is a good reason for it.

“A one-metre-long scarf made of lotus threads is worth about US$450,” Myint Thein Htun said. Behind him, a group of tourists are browsing a fine selection of pure lotus scarves, whose price tags go up to US$750.

The birth of this rare fabric is believed to go back more than a century, when a skilled weaver named Sa Oo noticed the fine fibres of lotus flowers blossoming across the lake.

The lotus’ beauty, symbolic of purity of the mind in Buddhism, inspired the devout artisan to turn its delicate filaments into a monk robe - a sacred offering of passionate devotion and purity of the soul. Legend has it that Sa Oo spent one whole year extracting and weaving lotus fibres into an exquisite garment for an abbot she revered.

Today, the lotus fabric of Inle Lake has travelled beyond the pious sphere and made its grand entrance into the world of luxury fashion.

Italian designer Pier Luigi Loro Piana, who runs high-end clothing company Loro Piana with his brother, was so mesmerised by the material’s fineness and painstaking production process that he introduced it to his product line.

A Loro Piana jacket made of Inle Lake’s lotus threads sells for US$5,600.

“The fabric looks similar to linen, but has the delicate fineness of raw silk,” says the label’s website.

“Only a few metres of fabric can be made, for a highly discerning audience.”

LOTUS WEAVING: A LABOUR OF FAITH

Just like its market value, the making of Myanmar’s lotus fabric is not for the faint of heart. It is a time-consuming process that takes untiring perseverance and a lot of passion.

It begins with sourcing the right material. Each year, lotus stems are harvested in the monsoon season. This is because its length elongates with the water level and its quality is considered best when the tides are high.

“The stem is long and fresh in deep water but short and weak in shallow areas,” said Myint Thein Htun. His family has been making lotus fabric for four generations and is renowned for its expertise in the craft.

“If we harvest in the dry season when the mud is less fertile, the stem won’t be strong enough.”

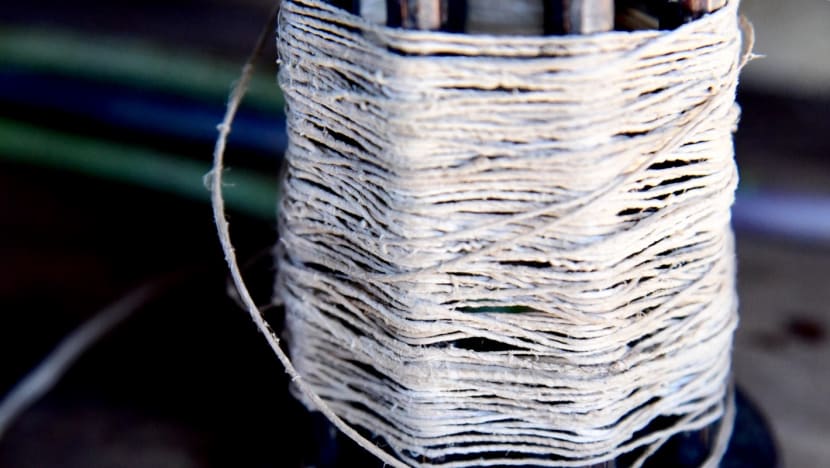

After the harvest, each stem is gently cut with a fine blade and carefully pulled apart to expose the delicate fibres within. These almost transparent filaments are then rolled on a moist surface into a thread.

The procedure is repeated again and again until the thread has the desired thickness and strength. Glue is then applied, followed by wax on each end to connect different strands together.

“The extraction can only be done by hand,” said Myint Thein Htun. “There is no way to do any of these with a machine.”

Finally, the thread is placed inside a shuttle and the weaving begins.

SACRED THREADS

Given their laborious production and sacred origin, lotus threads were mostly used for monk robes and coverings for Buddha images.

Today, their religious symbolism has inspired fashion designers to incorporate the material as part of their work. The result is contemporary apparel that not only commands attractive prices in the local textile market but also holds great spiritual values for customers.

“Demand for our products come from everywhere, from Taunggyi to Yangon and Mandalay,” said one of the local weavers, San San Mya.

“Our sales usually soar during Buddhist festivals. Ordination often takes place then and people want to offer lotus robes to monks.”

For many artisans behind the looms and spinning wheels, the arduous procedures of making lotus fabric are more than just a source of income. They are acts of piety - a pilgrimage of the soul as it pays homage to Buddhism.

“Lotus only grows in clear water, in rare places worthy for it to blossom,” the 52-year-old weaver added. “It has great spiritual significance and is therefore most worthy of any religious use.”

Yet, faith is not the only driving force that keeps her busy at the loom. Like many weavers, San San Mya is fascinated by this rare art form. The material’s delicate nature and complexity of its extraction process intrigues and challenges her. Each time she finishes weaving a piece of lotus fabric, there is always a rewarding feeling in her heart.

As she grows older, San San Mya wishes to pass on the knowledge to the younger generations. However, she doubts Myanmar youths would be interested in keeping this tradition alive.

“It’s very hard to find a young person who is keen on learning the art of lotus weaving, let alone being patient. They don’t want to do anything that involves hardship,” the weaver said.

“The price of lotus fabric will continue to rise but the number of weavers will fall.”

For more on this and other projects around Southeast Asia, tune in to Tapestry: The Heart of ASEAN on Channel NewsAsia every Tuesday from Feb 27 to Mar 27 at 11pm.