How the Singapore Mint makes commemorative coins

Did you know that commemorative coins are the only coins that are still made in Singapore? CNA's Gaya Chandramohan went behind the scenes at the Singapore Mint to watch how they are made by master craftsmen.

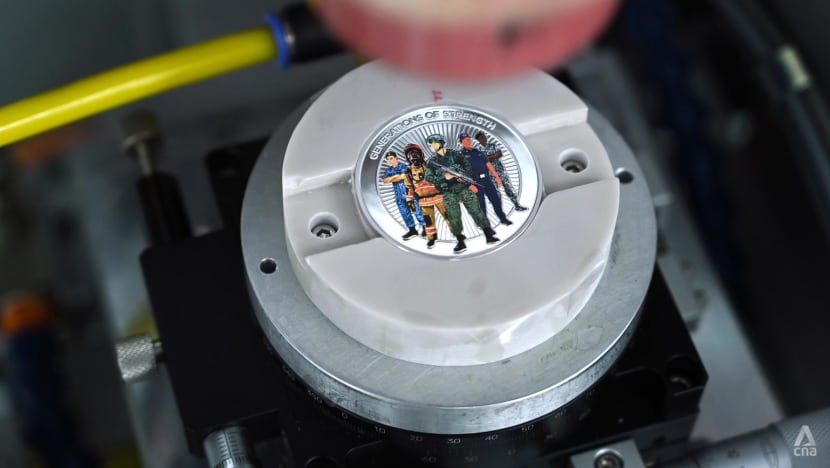

Freshly minted in the coin press machine: A medallion commemorating the 55th anniversary of National Service in Singapore. (Photo: CNA/Gaya Chandramohan)

SINGAPORE: In a dimly lit room, a woman adjusts her table lamp and shifts in her seat to peer into a microscope. With a sharp tool, she scores a piece of metal carefully while squinting into the eyepiece. Occasionally, she reaches for a bottle of solvent to douse it with.

She’s one of the master craftspeople at the Singapore Mint, showing CNA how coins and medallions are made from scratch.

Established in 1968, the Singapore Mint started out as a basic minting facility that made circulation coins for the country. Over half a century, it has evolved into an enterprise that produces commemorative coins and medallions for both local and international markets.

One of the mint’s most popular series is the Chinese almanac coin. Several variations of these coins are minted yearly with the appropriate zodiac animal. The mint also produces pop culture coins featuring movie franchises such as Star Wars, Harry Potter, and Marvel.

As the Singapore Mint no longer makes the country’s circulation coins, the commemorative coins are currently the only “made in Singapore” currency.

Here’s how these special coins are made.

COINING A DESIGN

At the heart of the mint’s operations is a team of highly skilled craftspeople that makes the coins – from the conceptual design and 3D rendering, to operating machines that strike the design with 1,000 tonnes of pressure.

All of it takes place in a nondescript building at Teban Gardens Crescent.

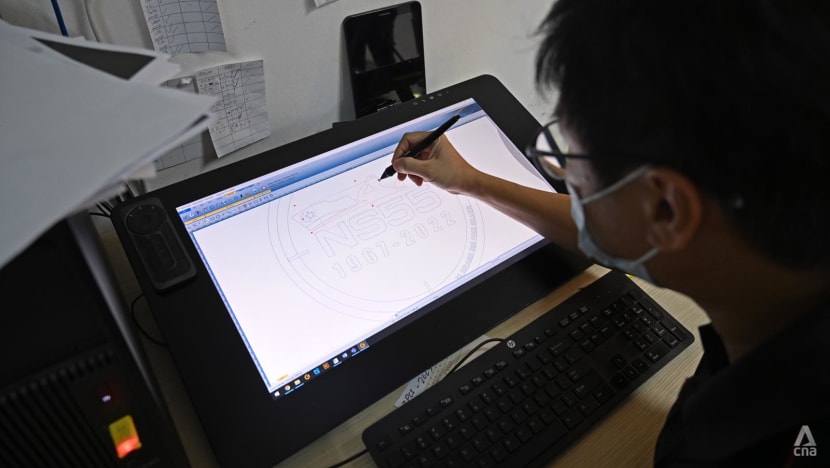

The process begins with digital sketches on modelling software. At this preliminary stage, finer details are omitted, to be added manually later.

MAKING THE MOULD

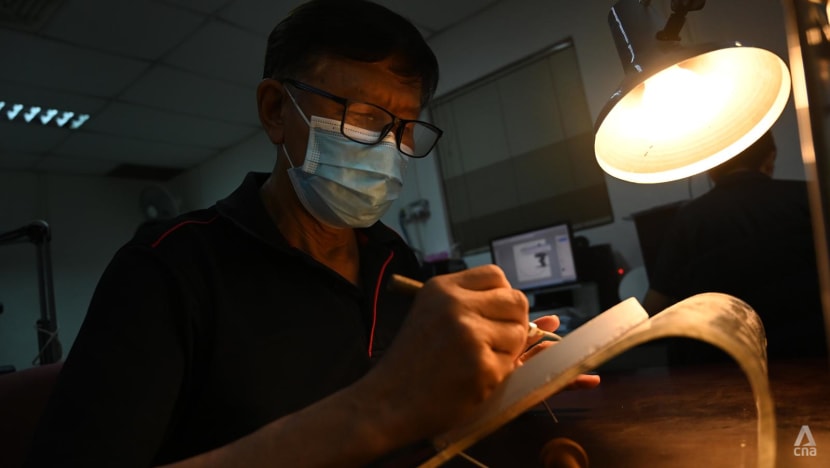

The design is used to create a plaster mould the size of a dinner plate. This is the canvas that the craftsmen of the Singapore Mint begin to work on.

With years of experience, the master craftsmen’s skill lies in adding intricate elements that technology cannot achieve – like facial expressions, for example.

While a machine can engrave the general likeness of a face, nuances that bring a design to life, such as a sparkle in the eye, fur on an animal, or a laugh line, are ones that can only be achieved by the human touch. It is this element of workmanship and artistry that the Singapore Mint prides itself on.

Armed with their arsenal of tools, it can often take the mint’s craftsmen several weeks to sculpt the fine details on the plaster mould.

No intricate detail is spared from the plaster mould – never mind that the final coin will be much smaller.

A rubber mould is made of the engraved plaster, so that the design can be transferred onto an epoxy mould, which is hard enough to be used as the coin’s final template.

HONEY, I SHRUNK THE COINS

The design now needs to be shrunk to the size of a coin.

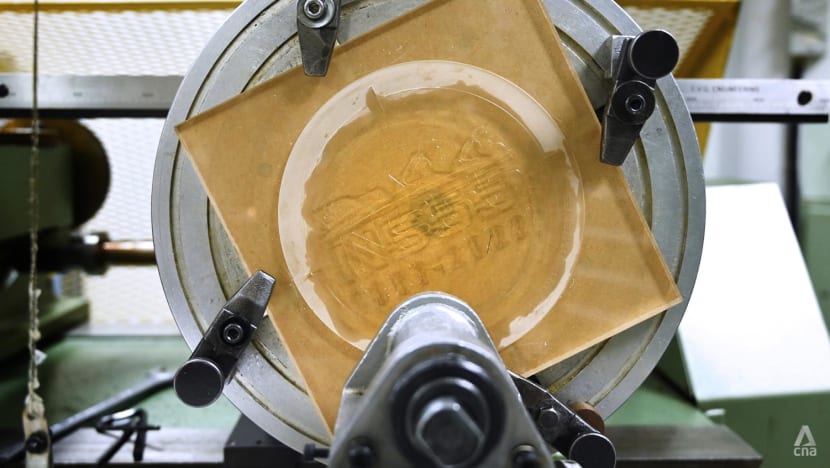

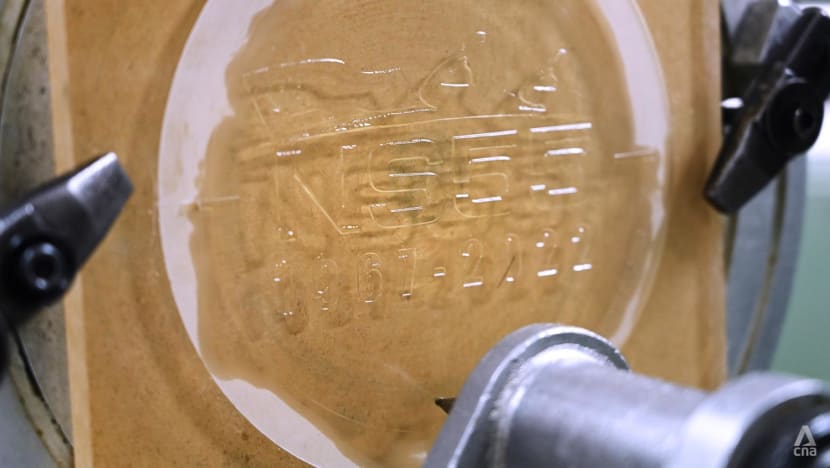

The rigid epoxy mould is loaded on one side of a pantograph machine, an instrument that copies large designs or drawings on a smaller scale. On the other side of the machine, there is a round, blank metal die.

As the pantograph fires up, both the epoxy mould and the metal die begin to spin.

A stylus traces the design on the large mould, and simultaneously, through a system of joint gears and pulleys, the movement of the stylus is mimicked on the surface of the metal die in miniature.

While pantographs are useful for shrinking down the designs, the resulting engravings are usually rough and unrefined. This is where the master craftsmen take over again with their skills. Using hand tools and a keen eye, a metal craftsman cleans up and polishes the engraving.

This becomes the master die for the coin.

The master die bears the positive image of the design. A die with a negative image - known as the working die – has to be produced for each side of the coin.

THE OTHER SIDE OF THE COIN

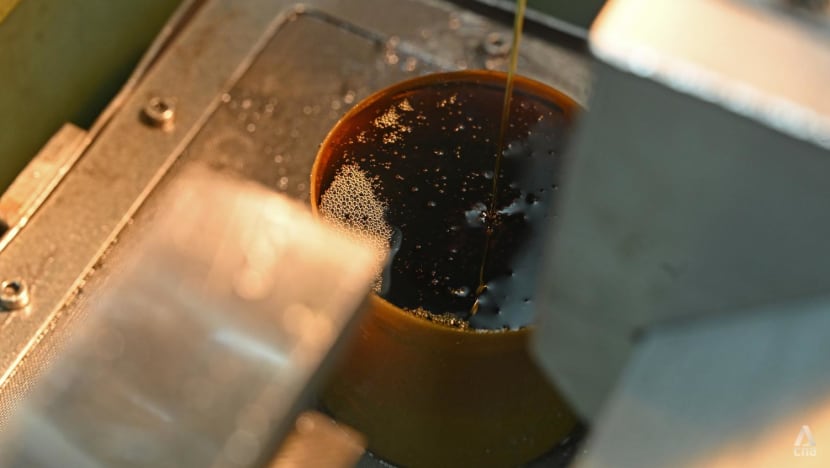

In the bowels of the Singapore Mint, thousands of blanks, often made of gold or silver, are prepared for stamping by workers at the coalface.

When blanks come in from suppliers, they are usually grubby and dusty, so each blank has to be cleaned thoroughly before they are stamped.

A mirror finish is required, so each blank has to be buffed by a machine and later by hand.

The machine takes up half the space in a cavernous basement room. It resembles an oversized lazy Susan with grey pipes extending to the ceiling. As it toils, it fills the room with a deafening noise.

A lone man sits at the slow-moving machine. His eyes are fixed on the many stands revolving on the belt, each with a round metal blank on it.

As the blanks move, they pass under large buffing wheels that polish the metal rounds to a shine. The worker loads and unloads the blanks and inspects them after polishing. Blanks that do not pass muster are rejected.

After being polished to a high shine, the blanks are treated with a solution and sent for a final manual polishing.

While handling the blanks, all workers wear latex finger cots to prevent fingerprints and natural oils on the skin from touching the surface.

The unmarked metal pieces undergo one last round of quality control before being stamped.

The mint tries to reduce the number of errors and potential rejects as each rejected piece is costly.

NEWLY MINTED

This is where the coins are finally struck - in another gargantuan machine about half the size of a bus.

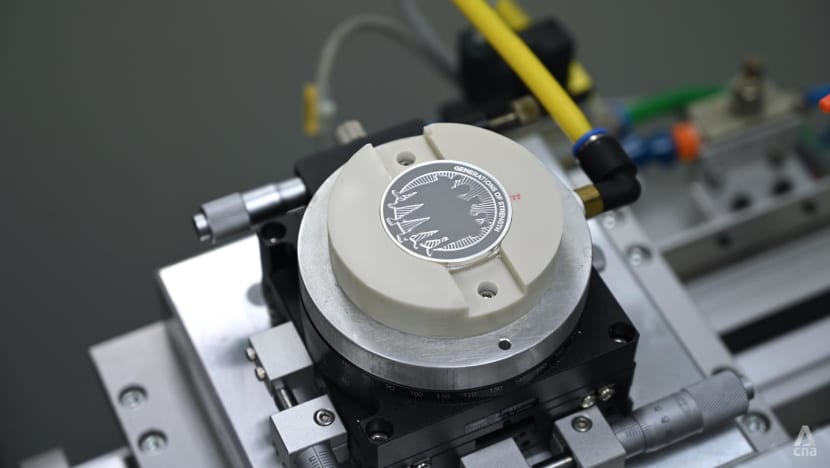

The working dies for both sides of the coin are installed, one on top and the other at the bottom, in the coin press machine.

The minter must ensure that both dies are aligned perfectly, or the coins would be struck off-kilter.

The worker places a blank between the two working dies, ensuring that it sits dead centre on the bottom die.

The machine is sealed for safety, and everything double-checked.

The minter pushes a button, and the machine strikes both sides of the blank simultaneously with 1,000 tonnes of pressure.

The newly minted coins are placed in their own capsules for packing.

Some are shipped off for further special effects, such as colouring or embedding of crystals in the coin.

COLOUR ME IMPRESSED

Some coins are designed in colour, and this step is done at the end, after the coin has been minted.

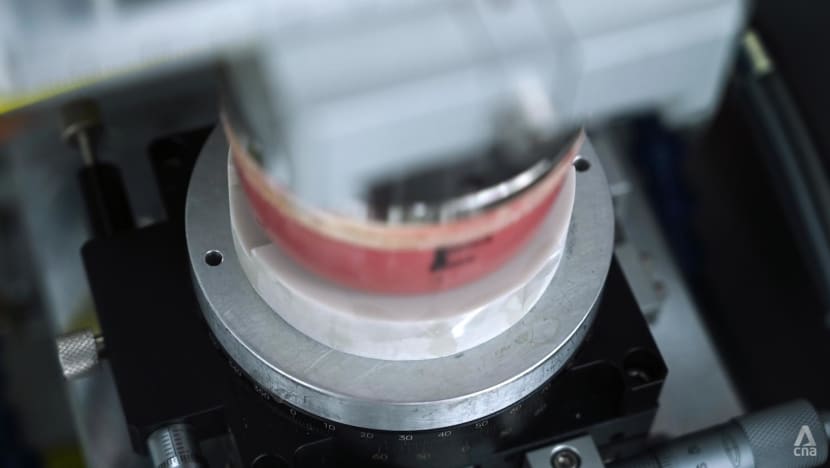

Over the years, the Singapore Mint has developed several state-of-the-art technologies that are kept highly confidential. One of them involves using a pad printing process to colour the coins and medallions, one shade at a time.

As the coin moves down a conveyor belt, soft silicone pads each apply a specific colour on the coin’s relief, or raised surfaces.

Each pad in succession adds a different colour to build the final picture.

After the last pad imprints its colour on the coin, the conveyor belt takes it back to a worker for a final inspection.