New healthcare R&D lab to explore 3D-printed body parts, customised medical implants

These innovations, which are currently still in development, could redefine patient treatment.

NTU’s Singapore Centre for 3D Printing (SC3DP) is able to print orthopaedic implants made from titanium-tantalum that can be customised to a patient’s unique anatomy, reducing the amount of surgical time in hospital. (Photo: NTU Singapore)

This audio is generated by an AI tool.

SINGAPORE: A new laboratory is looking at helping patients replace their missing or damaged body parts with 3D-printed versions.

Among the areas that the lab will cover are exploring 3D printing living tissues for regenerative medicine, which involves translating existing bioprinting research into practical clinical use, and developing 3D prosthetic and orthotic devices, including ankle foot orthosis and below-knee amputation sockets.

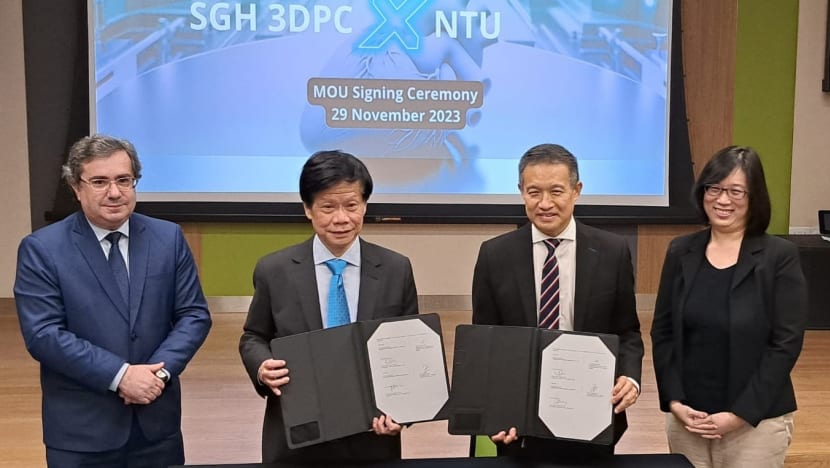

The joint research and development lab in additive manufacturing, a tie up between Nanyang Technological University (NTU) and Singapore General Hospital (SGH), is working on healthcare innovations such as bioprinting living tissues and customising medical devices and implants.

These innovations, which could redefine patient treatment, are currently still in development.

INNOVATIONS STILL BEING DEVELOPED

SGH CEO Kenneth Kwek said the possibilities that the tie-up can bring are limitless, adding: “We can advance care to enable better outcomes and a better experience for all patients and future users of healthcare.”

The collaboration leverages the combined expertise and resources of SGH’s 3D Printing Centre and NTU’s Singapore Centre for 3D Printing.

Professor Lam Khin Yong, vice president (Industry) at NTU, said the collaboration also benefits the next generation of clinicians, academics and engineers, equipping them with the skills and knowledge needed to navigate the changing medical landscape.

The lab will also focus on developing capabilities for 3D printing medical implants directly at the point-of-care, and enhancing the 3D healthcare technology landscape.

Currently, there is still a long process to go before the healthcare solutions can be implemented, said Professor Paulo Bartolo, executive director of the Singapore Centre for 3D Printing at NTU.

“The majority of the cases we are performing are preclinical studies in animals, so the next stage is human trials.”

Associate Professor Goh Su-Yen, clinical director with the Singapore General Hospital’s Future Health System department, said: “At the moment, the majority of the usage would be in printing surgical guides for cutting or anatomical models.”

Currently with these models, surgeons can visualise where the blood vessels and nerves are around a bone, for instance, and they can then plan a surgery with greater precision, she told CNA’s Singapore Tonight on Tuesday (Dec 12).

“This may reduce the time that the patient spends in the operating theatre.”

3D PRINTING LIVING TISSUES

Bioprinting is a relatively new subset of 3D printing for healthcare applications, said Prof Bartolo, who was also interviewed on the show.

“It is in an early stage of development, but basically with bioprinting, we use additive manufacturing machines to print biomaterials and cells to create tissues, to create organs, to be implanted or to be used as a model to study diseases and to study drugs.”

This essentially means that organs can be “printed”, “which is a holy grail”, said Prof Goh. “At the moment, the best thing we would have is an organ donation or a transplant.

“Now, we're talking about whether we can grow these organs, for example, skin, a pancreas, a liver or those cells in the lab. They would be compatible with the patient, and we could implant them.”

3D printing also allows the development of personalised medical devices, which are designed according to the patient's specific characteristics and needs, and can reduce costs.

However, there is a need to consider the materials used, especially if they are used inside the body.

“If we're just doing an anatomical model, it would be something as light as plastic,” said Prof Goh. “If we are going to be printing something that eventually gets implanted into a patient, then we have to consider weight and durability, or also whether the implanted material becomes a scaffolding and eventually dissolves.”

Prof Bartolo noted that there are two main considerations for the material used.

“The first is biocompatibility. So the material must avoid any adverse reaction or toxicity,” he added. “The second - and this is more related to materials used for bioprinting - (is that) they must be biodegradable.

“Besides that, we select materials according to specific applications based on mechanical properties, chemical characteristics. So there are a range of properties that we need to consider.”