MANUFACTURING CHANGE

WRITING A NEW

CHAPTER

Markono used technology to pivot from printing

to providing end-to-end solutions for publishers

around the world.

After taking over the reins of his family’s printing business, Mr Edwin Ng saw the shifting trends and recognised the need to change with the times. The business must transform in order to stay relevant. As the company’s Managing Director, Mr Ng continues to build on Markono’s core capability in printing honed over five decades and led the expansion into logistics and, more recently, e-commerce. Today, Markono provides services across its publishing customers’ entire value chain.

SCROLL

“When I first started, e-readers were fast becoming the trend. Will paper books go into history? I strongly believed that both options can co-exist. If we modernise and make ourselves more relevant, we could still have a viable business,” says Mr Ng (pictured).

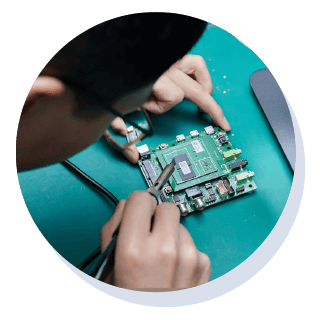

Going big on automation

Since the late 2000s, the homegrown company has been an early adopter of automation and innovation, enabling it to move into new growth areas.

SCROLL

When Mr Ng first joined Markono, the printing industry was disrupted by the arrival of e-readers, which

weakened the demand for physical publications. This prompted the firm to begin its transformation journey

to stay relevant.

New challenges, such as manpower shortages and rising raw material costs, also surfaced. In response,

Markono invested heavily in solutions, such as digital printing and print-on-demand, to improve efficiency

and generate new streams of revenue. These efforts manifest in its 275,000 sq ft integrated centre,

featuring state-of-the-art book manufacturing equipment and automated storage and retrieval technology.

“We built this facility to automate as many processes as we could. Now we have an enterprise resource planning

system that provides us with data and insights to help us streamline even further,” says Mr Ng. “Automation

allowed us to operate with less staff. But we still need people to learn new skills to manage the technology

and who can make good decisions in a dynamic environment.”

Today, this manufacturing and fulfilment facility prints over 6.7 million copies of books and journals every

year and serves eight of the world’s 10 largest international publishers, educational institutions and med-tech firms.

Singapore’s

manufacturing industry

Employed 9.3% of the workforce, or 212,100 people.

Offered higher gross median income of S$4,900 on average than the economy’s gross median income of S$4,700.

Singapore’s

manufacturing industry

Grew by 13.2%.

Received S$8.5 billion in total fixed asset investments, creating 6,000+ jobs when these projects are completed.

Manufacturing accounts for over 20 per cent of our GDP. We have bold plans to become an advanced manufacturing hub, with local enterprises like Markono at the heart of this vision.

- Sanjay Nanwani

Director (Manufacturing, Connectivity & Services), MTI

Tapping on tech talent and platforms

Markono’s new facility in Pioneer Crescent serves as a springboard for the company’s more ambitious plans — from ramping up its print-on-demand and logistics services to, most recently, launching an e-commerce platform known as BookSmart in 2021.

SCROLL

BookSmart offers Markono’s publishing customers a virtual shopfront to sell their books in the Asia Pacific.

The idea was first mooted at Enterprise Singapore’s Scale‑up SG programme,

which helps selected local companies grow and potentially become global champions.

Mr Ng says: “During the pandemic, our publishing customers were looking into more effective sales channels in this region.

“So we decided to be bold. We asked them to allow us to be their channel partner to sell their publications in this part of the world.”

Meanwhile, the company had to source for tech talent to support its new initiatives. By tapping on the

Digital Leaders Programme —

developed by the Infocomm Media Development Authority (IMDA) and Enterprise Singapore to support local companies in their digital

transformation plans — Markono was able to hire its first Chief Technology Officer.

MANUFACTURING 2030 CAREERS INITIATIVE

Initiatives to support MTI’s Manufacturing 2030 vision help manufacturing firms develop good career options for locals:

Manufacturing Employers’ Handbook: Provides the best human resource (HR) practices, tools and templates.

Additional quality internships: To be increased for engineering students from polytechnics and Institutes of Technical Education (ITEs).

Accelerated Pathways for Technicians & Assistant Engineers (Manufacturing) Grant: Supports companies in training and hiring ITE graduates for critical roles.

OTHER SCHEMES

AVAILABLE INCLUDE:

IMDA and Enterprise Singapore’s Digital Leaders Programme to accelerate digital transformation plans.

Enterprise Singapore’s Scale-up SG programme to help local companies scale effectively, and become leaders and future global champions.

Reading the future loud and clear

Among other plans, the company wants to use the data generated by its systems to provide more insights within its customers’ supply chains to augment their strategies.

SCROLL

“We optimise our customers’ entire value through our efficient and effective manufacturing processes and

end-to-end supply chain management,” says Mr Ng. “Instead of being a publisher’s supplier or manufacturer,

we want to be a true business partner.”

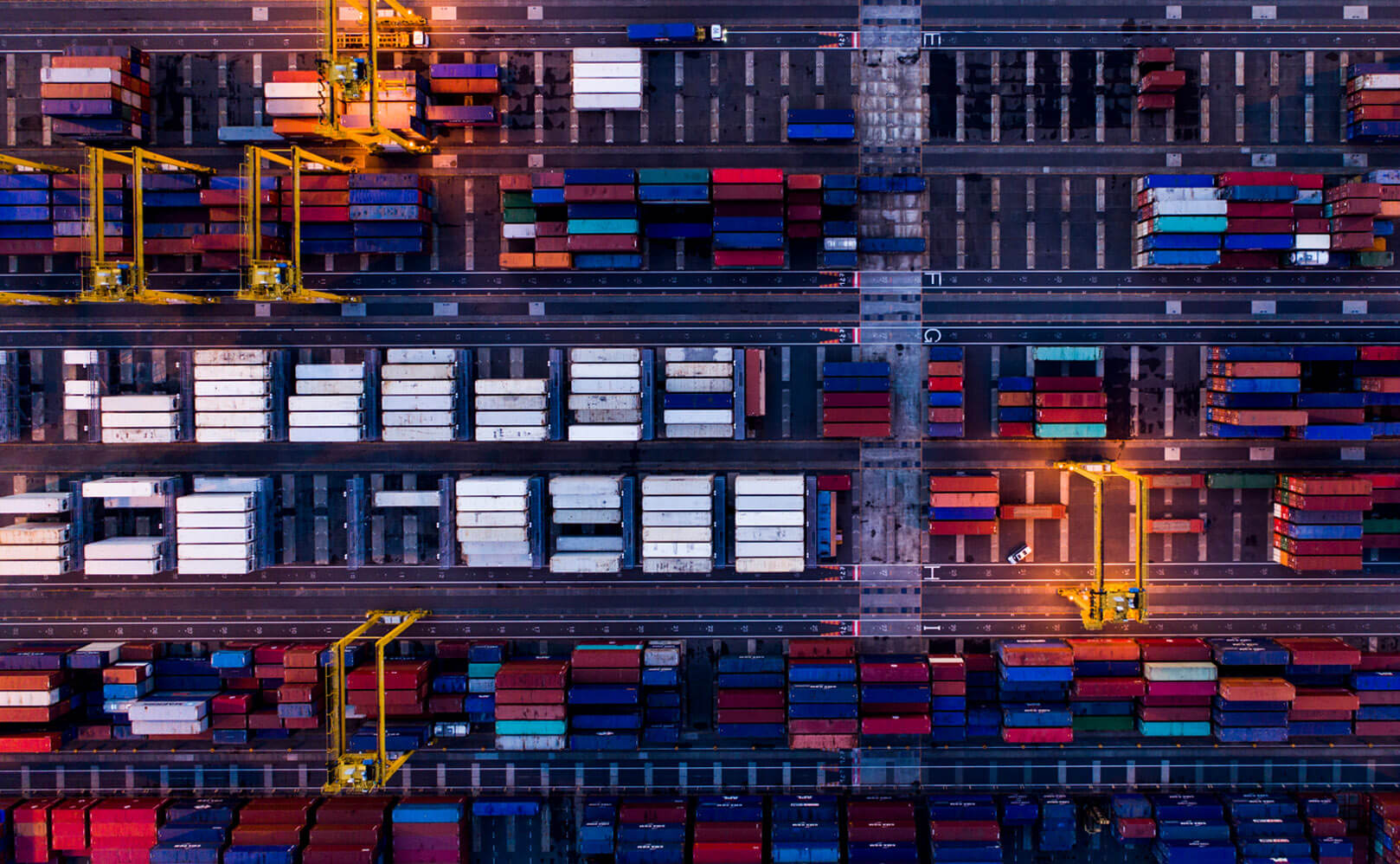

Markono is also investing in new logistics solutions, such as more automated picking and packing systems.

The ultimate goal of automation, however, is not to replace humans. Instead, says Mr Ng: “It is to allow

us to scale, to allow us to nurture new competencies in our people, preparing them for higher value-added roles.”

Singapore exports products worldwide and is a key player in sectors such as biomedical technology and pharmaceuticals. In the semiconductor industry, for example, the country accounts for 11 per cent of the global market and manufactures 20 per cent of equipment globally.

MTI’s Manufacturing 2030 vision:

GROW the sector’s added value by 50% by 2030,

DEVELOP a core of deeply innovative manufacturers, and

FORGE a robust local talent pipeline.

Your company’s

digitalisation

journey speaks

volumes.

More Stories

WRITING A NEW

CHAPTER

Markono used technology to pivot from printing to providing end-to-end solutions for publishers around the world.

After taking over the reins of his family’s printing business, Mr Edwin Ng saw the shifting trends and recognised the need to change with the times. The business must transform in order to stay relevant. As the company’s Managing Director, Mr Ng continues to build on Markono’s core capability in printing honed over five decades and led the expansion into logistics and, more recently, e-commerce. Today, Markono provides services across its publishing customers’ entire value chain.

SCROLL

“When I first started, e-readers were fast becoming the trend. Will paper books go into history? I strongly believed that both options can co-exist. If we modernise and make ourselves more relevant, we could still have a viable business,” says Mr Ng (pictured).

Going big on automation

Since the late 2000s, the homegrown company has been an early adopter of automation and innovation, enabling it to move into new growth areas.

SCROLL

When Mr Ng first joined Markono, the printing industry was disrupted by the arrival of e-readers, which

weakened the demand for physical publications. This prompted the firm to begin its transformation journey

to stay relevant.

New challenges, such as manpower shortages and rising raw material costs, also surfaced. In response,

Markono invested heavily in solutions, such as digital printing and print-on-demand, to improve efficiency

and generate new streams of revenue. These efforts manifest in its 275,000 sq ft integrated centre,

featuring state-of-the-art book manufacturing equipment and automated storage and retrieval technology.

“We built this facility to automate as many processes as we could. Now we have an enterprise resource planning

system that provides us with data and insights to help us streamline even further,” says Mr Ng. “Automation

allowed us to operate with less staff. But we still need people to learn new skills to manage the technology

and who can make good decisions in a dynamic environment.”

Today, this manufacturing and fulfilment facility prints over 6.7 million copies of books and journals every

year and serves eight of the world’s 10 largest international publishers, educational institutions and med-tech firms.

Singapore’s

manufacturing industry

Employed 9.3% of the workforce, or 212,100 people.

Offered higher gross median income of S$4,900 on average than the economy’s gross median income of S$4,700.

Singapore’s

manufacturing industry

Grew by 13.2%

Received S$8.5 billion in total fixed asset investments, creating 6,000+ jobs when these projects are completed.

Manufacturing accounts for over 20 per cent of our GDP. We have bold plans to become an advanced manufacturing hub, with local enterprises like Markono at the heart of this vision.

- Sanjay Nanwani

Director (Manufacturing, Connectivity & Services), MTI

Tapping on tech talent and platforms

Markono’s new facility in Pioneer Crescent serves as a springboard for the company’s more ambitious plans — from ramping up its print-on-demand and logistics services to, most recently, launching an e-commerce platform known as BookSmart in 2021.

SCROLL

BookSmart offers Markono’s publishing customers a virtual shopfront to sell their books in the Asia Pacific.

The idea was first mooted at Enterprise Singapore’s Scale‑up SG programme,

which helps selected local companies grow and potentially become global champions.

Mr Ng says: “During the pandemic, our publishing customers were looking into more effective sales channels in this region.

“So we decided to be bold. We asked them to allow us to be their channel partner to sell their publications in this part of the world.”

Meanwhile, the company had to source for tech talent to support its new initiatives. By tapping on the

Digital Leaders Programme —

developed by the Infocomm Media Development Authority (IMDA) and Enterprise Singapore to support local companies in their digital

transformation plans — Markono was able to hire its first Chief Technology Officer.

MANUFACTURING 2030 CAREERS INITIATIVE

Initiatives to support MTI’s Manufacturing 2030 vision help manufacturing firms develop good career options for locals:

Manufacturing Employers’ Handbook: Provides the best human resource (HR) practices, tools and templates.

Additional quality internships: To be increased for engineering students from polytechnics and Institutes of Technical Education (ITEs).

Accelerated Pathways for Technicians & Assistant Engineers (Manufacturing) Grant: Supports companies in training and hiring ITE graduates for critical roles.

MANUFACTURING 2030 CAREERS INITIATIVE

Initiatives to support MTI’s Manufacturing 2030 vision help manufacturing firms develop good career options for locals:

OTHER SCHEMES AVAILABLE INCLUDE:

IMDA and Enterprise Singapore’s Digital Leaders Programme to accelerate digital transformation plans.

Enterprise Singapore’s Scale-up SG programme to help local companies scale effectively, and become leaders and future global champions.

Reading the future loud and clear

Among other plans, the company wants to use the data generated by its systems to provide more insights within its customers’ supply chains to augment their strategies.

SCROLL

“We optimise our customers’ entire value through our efficient and effective manufacturing processes and

end-to-end supply chain management,” says Mr Ng. “Instead of being a publisher’s supplier or manufacturer,

we want to be a true business partner.”

Markono is also investing in new logistics solutions, such as more automated picking and packing systems.

The ultimate goal of automation, however, is not to replace humans. Instead, says Mr Ng: “It is to allow

us to scale, to allow us to nurture new competencies in our people, preparing them for higher value-added roles.”

Singapore exports products worldwide and is a key player in sectors such as biomedical technology and pharmaceuticals. In the semiconductor industry, for example, the country accounts for 11 per cent of the global market and manufactures 20 per cent of equipment globally.

MTI’s Manufacturing 2030 vision:

GROW the sector’s added value by 50% by 2030,

DEVELOP a core of deeply innovative manufacturers, and

FORGE a robust local talent pipeline.

Your company’s digitalisation journey speaks volumes.

FIND OUT MORE