Fires, oil leaks and smoke: What led to the Tuas explosion that killed 3 workers

A photo of a glowing flange taken by worker Anisuzzaman Md and sent at 8.39am the day of the Tuas explosion on Feb 24, 2021. (Photo: Report of the Inquiry Committee for the accident at Stars Engrg Pte Ltd)

SINGAPORE: An inquiry committee that looked into the Tuas explosion that killed three workers and injured seven others in February last year published its report on Friday (Mar 25), documenting multiple red flags such as fires, oil leaks and smoke before the fatal incident.

The 89-page document also laid out evidence from experts on how the explosion was caused by the unsafe use of a mixer machine, resulting in gradual degradation and an accumulation of pressure on the machine.

The explosion eventually ignited accumulated potato starch powder suspended in the air, resulting in the subsequent flash fires on Feb 24, 2021.

The committee also recommended steps to improve safety, and concluded that criminal offences had been disclosed in acts and omissions by Stars Engrg and two key personnel.

Here are the highlights from the report:

THE ACCIDENT

Stars Engrg’s core business is the installation of fire protection systems. It uses a fire-rated insulation wrap under the brand name “Shield+” to wrap piping and ducting systems in buildings. Mr Chua Xing Da is the director of Stars Engrg and Shield+.

The explosion happened on Feb 24, 2021 at the company’s premises at 32E Tuas Avenue 11, resulting in three deaths, five major injuries, two minor injuries, and severe property damage.

At about 8.30am, two workers were preparing a mixer machine to mix potato starch powder with heated water, to produce “fire clay” that would be used in fire retardant sheets. Six other workers were at the worksite.

A flange connected to one of the machine’s heating elements was noticed to be glowing, and it is understood that the workers shut down the machine to allow it to cool down.

At 11.22am, the explosion occurred. All eight workers from Stars Engrg suffered burns and two workers from P3 Project, who were working at the unit opposite of Stars Engrg, were also injured.

The workers who died were supervisor Mr Subbaiyan Marimuthu, 38, an Indian national; Mr Anisuzzaman Md, 29 and Mr Shohel Md, 23, both from Bangladesh.

They suffered about 90 per cent full thickness burns.

Five other Bangladeshi workers from Stars Engrg were injured: Mr Ahmmed Lizon, 25, Mr Hossain Jitu, 32, Mr Mehedi, 21, Mr Molla Md Yousuf, 27 and Mr Rahad Asfaquzzaman, 30. They reported being thrown off their feet due to the force of the explosion.

Mr Miah Md Azam, 39, and Mr Zhao Jian Wang, 44, from P3 Project were also hurt.

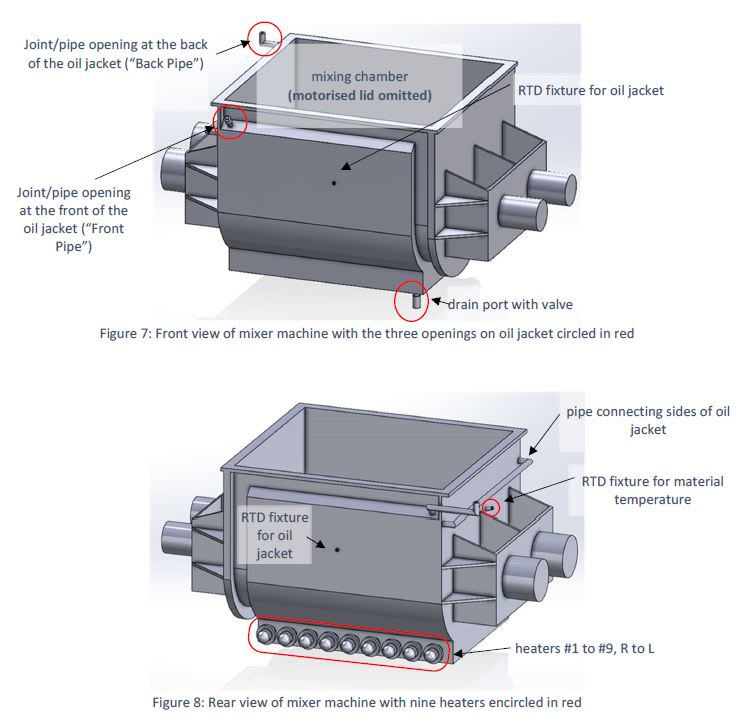

THE MACHINE

The machine was used to make “fire clay”, a main component of fire-retardant wraps or “fire wrap”.

It is similar to other mixer machines used to mix ingredients such as flour and water, but comes with an external oil jacket for heat transfer fluid and built-in heaters for heating of the contents.

A key ingredient for the “fire clay” is potato starch powder.

To make the clay, the workers were required to use the machine to first heat up water in its mixing chamber, then added potato starch and other ingredients until they achieved a paste.

This fire clay would then be wrapped with other components such as ceramic fibre and fibreglass within aluminium sheets to form the end product, “fire wrap”.

The machine was ordered via online platform Alibaba in August 2019. It was manufactured by Laizhou Keda Chemical Machinery and delivered to Stars Engrg sometime between October and November 2019.

RED FLAGS & WARNING SIGNS

The report listed a series of red flags spotted months before the explosion occurred. These included boiling sounds during the operation of the machine as well as white smoke and oil leaks from the oil jacket. The heaters on the machine also melted, glowed red or caught fire.

On the morning of the explosion on Feb 24, a heater glowed red hot and a small fire occurred at the heater area.

This was not the first time a fire had broken out. On Feb 12, a fire also broke out at the front of the mixer machine. Black oil was observed to have leaked from the oil jacket and there was a lot of smoke.

After that fire, Mr Marimuthu developed concerns about the safety of the mixer machine and sent a series of concerned messages via WhatsApp to project manager Lwin Moe Tun.

“this one finish I talk to you”

“better I no work”

“I very sect [scared]”

“still I no see my baby”

Mr Lwin told Mr Chua about Mr Marimuthu's concerns. In response, Mr Chua sent several text messages to Mr Marimuthu claiming that the fire was not actually from the mixer machine, the machine was not dangerous, and it was not the oil that caught fire.

This was just one such incident. The report said: “These events were near misses and opportunities for intervention. However, they were not thoroughly investigated because the occurrences were not adequately understood, and no further risk assessments were conducted.

“Had the red flags been properly addressed, the unfortunate explosion could have been avoided.”

HOW THE EXPLOSION OCCURRED

There were two main circumstances leading to the explosion:

First, excessive pressure in the mixer machine’s oil jacket caused mechanical failure and fracture of the welds.

This pressure was a result of over-heating of the oil and use of the oil jacket as a closed system when it was designed to be operated as an opened system, said the report.

Mr Chua had instructed Stars Engrg’s workers to seal off all openings on the oil jacket since Aug 8, 2020, the report said.

Second, when the welds fractured from too much pressure in the oil jacket, oil was forced out and aerosolised into fine droplets, which were ignited, leading to the explosion.

This sparked off the accumulated potato starch powder suspended in the air, causing the subsequent flash fires.

“UNSAFE USE OF MACHINE”

The committee concluded that the accident was “rooted in the unsafe use of the mixer machine”.

These were the instances listed:

- The temperature within the oil jacket was not monitored. The temperature sensor that came with the mixer machine to measure and regulate the temperature within the oil jacket was used interchangeably with another temperature sensor that was meant to measure only the temperature within the mixing chamber.

- Insufficient oil in the machine’s oil jacket caused inefficient heat transfer and overheating. The thermal degradation of the oil significantly reduced its flash point.

- The mixer machine was used as a closed system with the two vents sealed off, without monitoring of the pressure within the oil jacket.

- The repeated heating and cooling cycle each time the mixer machine was used stressed the oil jacket’s integrity, and it lost its mechanical strength.

- This was exacerbated by the weakening of the weld seams due to poor repair welds done by Stars Engrg’s workers. As a consequence, the oil jacket ruptured outwards at the weak points, fracturing at the weld seams.

POTATO STARCH POWDER

After the initial explosion, which caused the most significant damage and injuries, there were secondary, smaller flash fires, which were most likely due to the combustion of the potato starch powders.

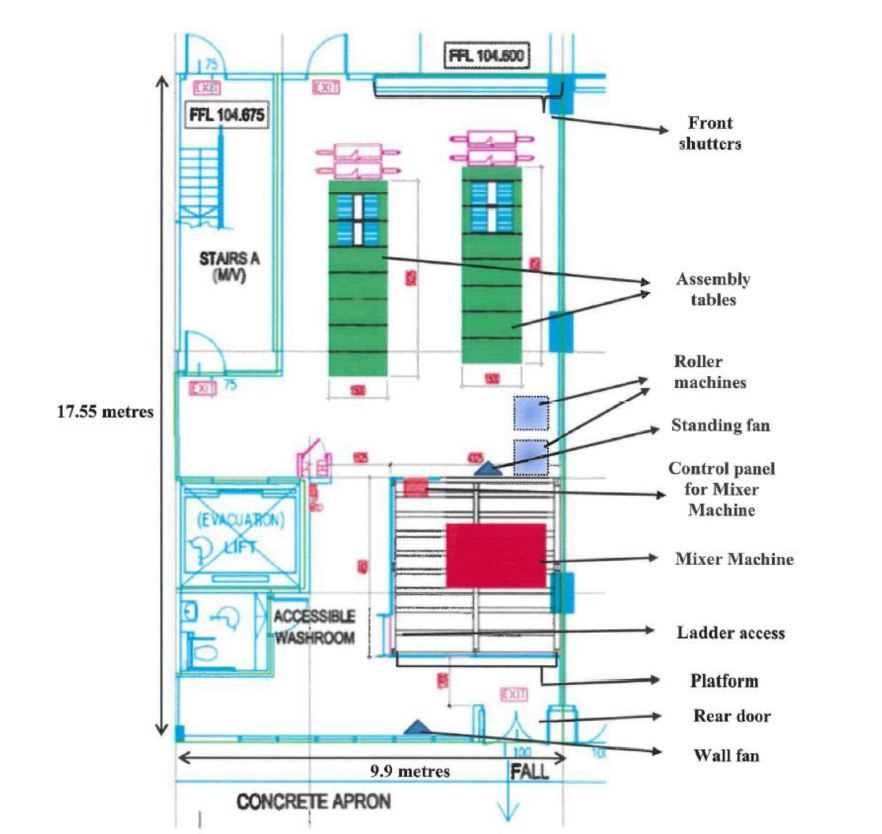

As there were neither a local exhaust ventilation system to capture residual powder nor adequate housekeeping to keep the workplace dust-free, the combustible potato starch powder was able to disperse and accumulate within the worksite.

A fan mounted on the rear wall just behind the mixer machine further facilitated the dispersion of the powder.

Based on CCTV footages from a neighbouring unit, there were at least three secondary flash fires following the initial chemical explosion.

The report also highlighted other safety gaps such a inadequate risk assessment for the operation of the machine, the lack of an emergency response plan and personal protective equipment.

For example, one worker was at an assembly table near an emergency exit just before the explosion. But the exit was obstructed with a drilling machine, aluminium rolls and a gas cylinder and he had to jump over the table to escape.

POSSIBLE CRIMINAL LIABILITIES

Due to many of the lapses detailed above, the committee said that Stars Engrg “failed in its duty” as an occupier of the worksite and as an employer.

On Mr Chua, it said that he installed and commissioned the mixer machine by himself despite having insufficient knowledge on how it was to be safely used.

“Chua had made ill-founded assumptions when dealing with the operation, modifications, and failures of the mixer machine, and had been the person responsible for instructing Stars Engrg’s workers on dealing with the mixer machine,” the report said.

Both he and Mr Lwin are also potentially liable for “obstructing the course of justice”, as they lied to MOM’s investigators regarding some WhatsApp messages between Mr Lwin and Mr Marimuthu on the machine, which Mr Lwin had deleted.

The report also said: “The evidence revealed that (Mr Lwin) had, at the very least, been negligent and endangered the safety and health of others.”

RECOMMENDATIONS

The inquiry committee recommended the following:

- Encourage buyers of industrial equipment to certify their purchased equipment to industrial standards.

- Promote safe use of combustible dusts: Suppliers of materials that pose a defined level of combustible dust hazard should include a label explicitly informing on the hazard before selling or redistributing.

- Companies that handle prescribed amounts of specified combustible powders to register or notify the authorities.

- Occupiers should inform building owners or landlords on the use of combustible powders, so that they can "deconflict" incompatible work among tenants, if any.

- More outreach and guidance efforts should be conducted, specifically directed towards small- and medium-size enterprises, as well as workers who may be at risk.