Cost of treating and supplying water in Singapore up significantly, says PUB

Due to higher construction and manpower costs, the second phase of the Deep Tunnel Sewerage System will cost S$6.5 billion – almost twice that of the first phase.

SINGAPORE: The cost of treating and supplying water has risen significantly with energy and construction costs driving up expenses, said national water agency PUB on Friday (Sep 22).

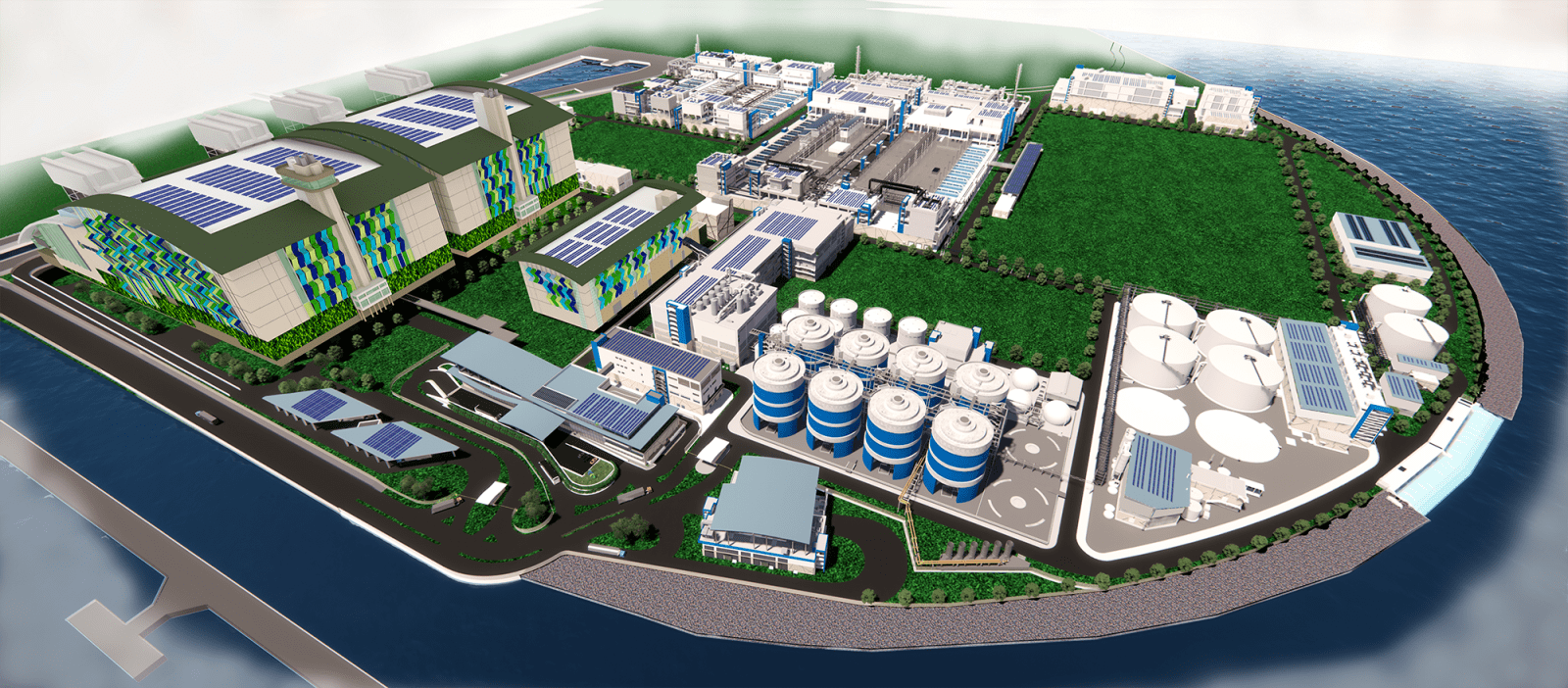

Achieving water security has become “more challenging” globally and Singapore is no exception, PUB said during a progress update of the Tuas Water Reclamation Plant. About a third of the plant – a key component in the second phase of Singapore’s Deep Tunnel Sewerage System (DTSS) – has been completed.

Some of the challenges include climate change which has increased the frequency of extreme weather, increased water demand that is projected to almost double by 2065, as well as external cost pressures due to global supply chain disruptions and geopolitical events.

“These external cost pressures are not unique to PUB,” said the agency, highlighting the increased costs for energy, construction, chemicals and maintenance.

Energy costs have gone up as the average electricity tariffs increased by almost 37 per cent since 2017 – and about 50 per cent at its peak – due to rising fuel prices.

“With increasing water demand, PUB needs to tap on more energy-intensive supply sources such as desalination and NEWater, and treat more used water,” said the agency.

Overall construction costs in Singapore have gone up by 35 per cent since 2017.

Constructing water infrastructure in an increasingly urbanised environment is more costly as it involves building more compact structures to lower land footprint, and adopting less-intrusive construction methods to minimise the need for road or utility diversions, said PUB.

Citing an example of a less-intrusive method of constructing pipelines known as pipejacking, PUB said the cost of using this method is now S$17 million (US$12.4 million) for every kilometre - a 70 per cent increase from the S$10 million per km in 2017.

Due to higher construction and manpower costs, the second phase of DTSS will cost S$6.5 billion. This is almost twice that of Phase 1, which cost S$3.4 billion when it was built almost two decades ago, said PUB. The cost of constructing the deep tunnels for Phase 2 has also more than tripled, the agency added.

In addition, the operating expenses for chemicals, which are key materials in the water treatment process, have grown by about 33 per cent since 2017. The maintenance costs of the water system have also risen by 18 per cent, as COVID-19 and supply chain disruptions have driven increases in costs for manpower and parts for the water system.

SAVING ENERGY, SPACE AND COSTS

To improve energy efficiency, the Tuas Water Reclamation Plant will incorporate water treatment technologies to allow the plant to generate 80 per cent of the energy it requires to treat used water. This is a “vast improvement” compared to the 25 per cent at the water reclamation plants in Ulu Pandan and Jurong, said PUB.

The plant will also increase the rate of NEWater recovery without using additional energy.

To offset higher construction costs, treated effluent will be directly discharged into the sea. This way, a long and deep discharge pipe need not be constructed, which would have cost at least S$650 million, said PUB.

The national water agency added it will also implement technologies at the Tuas Water Reclamation Plant for 30 per cent more compact treatment units compared to the conventional ones, thus reducing land footprint.

Biological treatment processes for odour control and primary treatment of used water will be deployed at the plant to reduce the need for chemicals.

PUB added that it is also implementing smart technologies such as online sensors and automated systems to ensure the plant’s operations are cost- and manpower-efficient.